| Model | Effective Measurement Travel mm | Dimensions (L*W*H) mm | |||

| X-axis | Y-axis | Z-axis | Machine dimensions | Package dimensions | |

| MVS322 | 300mm | 200mm | 200mm | (1146*720*1664)mm | (1290*970*1920)mm |

| MVS432 | 400mm | 300mm | 200mm | (1331*840*1664)mm | (1390*1060*1940)mm |

| MVS542 | 500mm | 400mm | 200mm | (1257*920*1640)mm | (1450*1170*1900)mm |

| No. | Reference configuration | Qts |

| 1 | DELL Optiplex Desktop | 1 |

| 2 | G6405 Processor | 1 |

| 3 | 8G DDR4 2666 memory | 1 |

| 4 | M.2 2280 NVME 250G SSD | 1 |

| 5 | Intel UHD graphics card PCIE dual network port card | 1 |

| 6 | 21.5" monitors | 1 |

| 7 | Win10 64bit | 1 |

| 8 | 100-240V adaptive power supply | 1 |

| 9 | MS116 Mouse Set | 1 |

| Sensor Configuration | 2.5D | 3D | Semiauto 2.5D | Semiauto 3D |

| Model | MVS-322A | MVS-322B | MVS-322C | MVS-322D |

| Suffix | A | B | C | D |

| Suffix Meaning | Optics | Optics + Probe | Optics + Laser | Optics + Probe + Laser |

| Use Range | Point • | Point • | Point • | Point • |

| Line — | Line — | Line — | Line — | |

| Circle ○ | Circle ○ | Circle ○ | Circle ○ | |

| Arc ⌒ | Arc ⌒ | Arc ⌒ | Arc ⌒ | |

| Ellipse | Ellipse | Ellipse | Ellipse | |

| Rectangle | Rectangle | Rectangle | Rectangle | |

| Circular Groove | Circular Groove | Circular Groove | Circular Groove | |

| Ring | Ring | Ring | Ring | |

| Closed Curve | Closed Curve | Closed Curve | Closed Curve | |

| Open Curve | Open Curve | Open Curve | Open Curve | |

| High Magnification Height Measurement | Probe height measurement | Laser height measurement | High-efficiency laser height measurement and stable probe height measurement | |

| ------ | Simple Regular 3D Dimensions | ------ | Simple Regular 3D Dimensions | |

| Computable | Distance | Distance | Distance | Distance |

| Angle ∠ | Angle ∠ | Angle ∠ | Angle ∠ | |

| Diameter φ | Diameter φ | Diameter φ | Diameter φ | |

| Radius ® | Radius ® | Radius ® | Radius ® | |

| Roundness ○ | Roundness ○ | Roundness ○ | Roundness ○ | |

| Straightness | Straightness | Straightness | Straightness | |

| Parallelism | Parallelism | Parallelism | Parallelism | |

| ------ | Perpendicularity | ------ | Perpendicularity | |

| Concentricity | Concentricity | Concentricity | Concentricity | |

| Angularity | Angularity | Angularity | Angularity | |

| Symmetry | Symmetry | Symmetry | Symmetry | |

| Flatness | Flatness | Flatness | Flatness | |

| 2D Position | 2D Position | 2D Position | 2D Position |

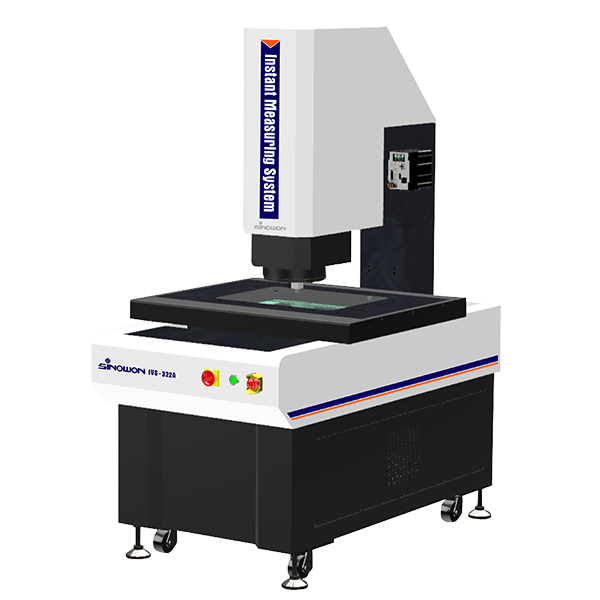

| Commodity | 2.5D Automatic Vision Measuring Machine | 3D Automatic Contact & Vision Measuring Machine | 2.5D Automatic Laser-Scan & Vision Measuring Machine | 3D Automatic Multisensory Measuring Machine | ||||||||||

| Model | MVS-322A | MVS-322B | MVS-322C | MVS-322D | ||||||||||

| Code# | 522-120G | 522-220G | 522-320G | 522-420G | ||||||||||

| Sensor-Type | A: One-Sensor Optical Zoom-lens Sensor | B: Twin-Sensor Zoom-lens Sensor and Contact Probe Sensor | C: Twin-Sensor Zoom-lens Sensor and Confocal Laser Sensor | D: Tri-Sensor Zoom-lens Sensor Contact Probe Sensor Confocal Laser Sensor | ||||||||||

| X/Y-axis Travel | (300*200)mm | |||||||||||||

| Z-axis Travel | 200mm | |||||||||||||

| X/Y/Z-3 axis Linear Scale | European Linear Scale Resolution: 0.5um | |||||||||||||

| Guidance Mode | P-Class Precision linear guide, double-track double slider guide. | |||||||||||||

| Operation Mode | Joystick controller, Mouse operation, automatic detection program. | |||||||||||||

| Accuracy* | XY-axis:≤2.2+L/200(um) | |||||||||||||

| Z-axis:≤5.0+L/200(um) | ||||||||||||||

| Repeatability | ±2um | |||||||||||||

| Video System** | 1/2.9"/1.6Mpixel High Resolution Digital Camera | |||||||||||||

| 8.3X Manual Electronic Feedback Lens | ||||||||||||||

| Optical Magnification: 0.6X~5.0X; Video Magnification: 20X~170X (21.5” monitor) | ||||||||||||||

| Field of View(mm) (D*H*V) | Magnification | 0.6X | 1X | 1.5X | 2X | 2.5X | 3X | 3.5X | 4X | 4.5X | 5X | |||

| 1/2.9"CCD | 10.35x8.28x6.21 | 6.21x4.97x3.73 | 4.14x3.31x2.48 | 3.11x2.48x1.86 | 2.48x1.99x1.49 | 2.07x1.66x1.24 | 1.77x1.42x1.06 | 1.55x1.24x0.93 | 1.38x1.10x0.83 | 1.24x0.99x0.75 | ||||

| Illumination System | Contour | LED parallel contour illumination | ||||||||||||

| Surface | 0~255 Stepless adjustable 5-ring 8-division LED surface illumination | |||||||||||||

| Measuring Software | iMeasuring Software | |||||||||||||

| Load Capacity | 25Kg~50Kg | |||||||||||||

| Working Environment | Temperature 20℃±2℃, temperature change<1℃/Hr; humidity 30%~80%RH; vibration<0.02g's, ≤15Hz. | |||||||||||||

| Power Supply | 220V/50Hz/10A | |||||||||||||

| Dimension (W*D*H) | (1146mm*720mm*1664)mm | |||||||||||||

| Packing Size | (1290*970*1920)mm | |||||||||||||

| Net Weight | 380Kg | |||||||||||||