IVS Series Solution To Auto-Production Line

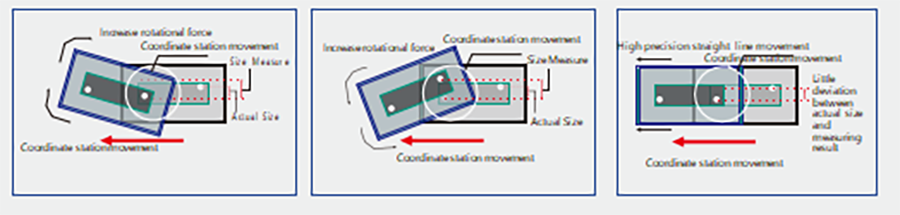

Solve the Inherent Problems In Dimension Measurement

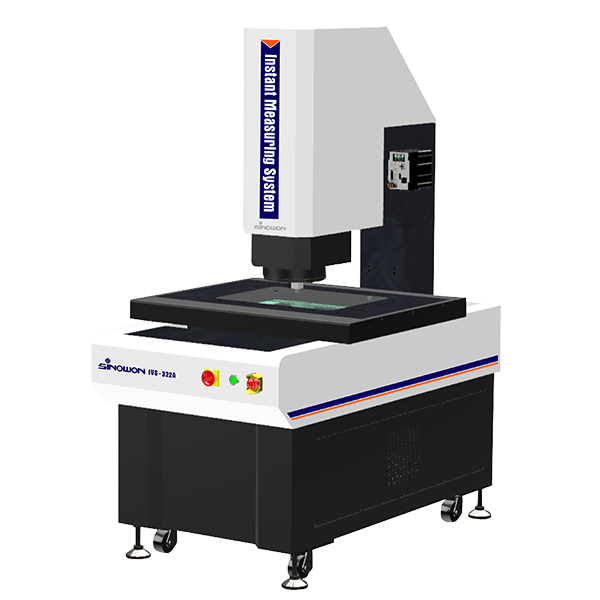

Benchtop Instant Measurement System ● Table structure, compact size, easy to handle. ● One-Button Measurement,can also be matched with IO signal to achieve automatic measurement. ● The report can be uploaded automatically into data management system. High Precision Measurement Under Surface Light ● Equipped with Double Magnification Telecentric Lens and two 20MP camera, auto multi-angle surface light and optional coaxial surface light. ● With the independent powerful AI edge calculation algorithm, it can easily realize precise edge searching on the surface and filter invalid areas for boundary clutter. ● The measurement repeatability of surface light can also reach the similar level as that of bottom light. Fast Measurement And Easy Operation ● Can measure 100 dimensions in one second, greatly reducing the measurement time. ● The operation interface of the software is simple and easy to be understood, and the measurement program and parameter setting can be easily written. ● With automatic focusing, automatic positioning and automatic measurement function, anyone operation can obtain stable measurement results.

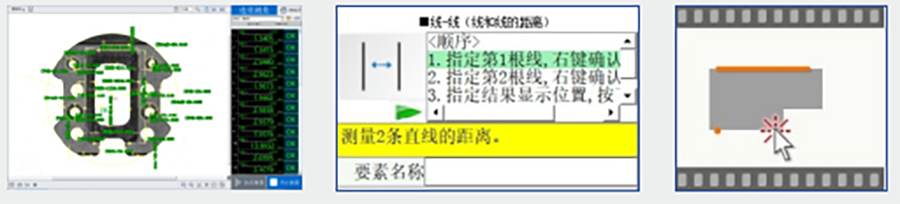

Detection report and statistical report can be completed through one-click production, without data transmission and computer input and other tedious process, support a variety of formats. It can also be automatically uploaded to the customer data management system.

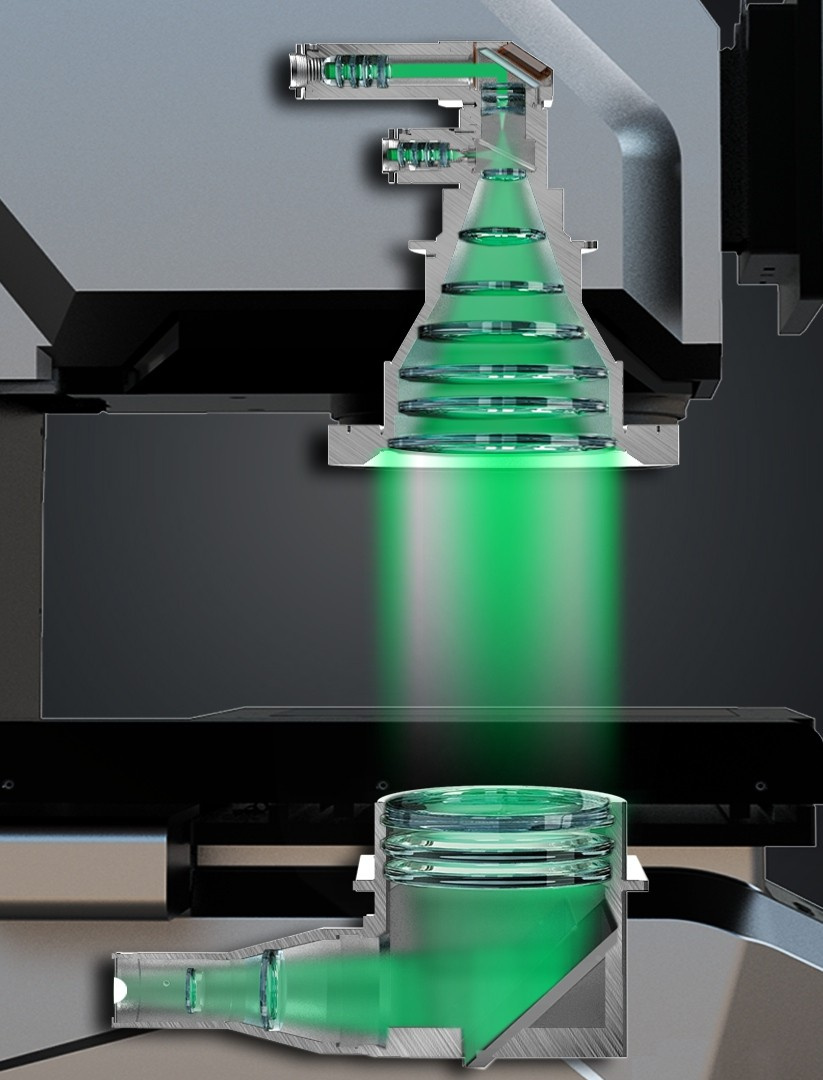

Equipped with Double Magnification Telecentric Lens and two 20MP camera, auto multi-angle surface light and optional coaxial surface light. With the independent powerful AI edge calculation algorithm, it can easily realize precise edge searching on the surface and filter invalid areas for boundary clutter. The measurement repeatability of surface light can also reach the similar level as that of bottom light.

Convenient | One-Button for Measuring

One-Button for Measuring

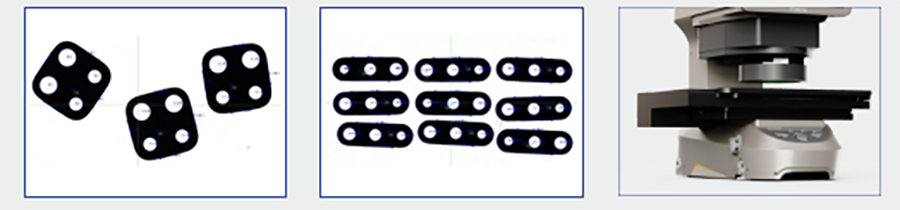

One-Button for Measuring Through the positioning function, it can automatically identify the position and direction of the product. The product is placed randomly on the platform, and it can be measured by pressing one button. It can also be matched with the CUSTOMER IO signal to achieve automatic measurement.

Benchtop Structure Compact feature, benchtop structure, easy to handle, the system can adapt to a variety of environments. It is suitable for in-line size measurement.

Using a 1’’ 20-megapixel black-and-white camera, the number of pixels has been increased to two times that of traditional models, and the tiny edges that were difficult to observe in the past can also be observed. With movable measurement, field of view switching, the system can achieve high precision and wide field measurement, while improving accuracy and shortening measurement time.

Set multiple lighting units into one with lifting multi-angle surface light. The software is equipped with light automatic adjustment function. Through the built-in brightness sensor for different ambient light source, the system can automatically adjust to the best lighting conditions.

The system can measure 100 dimensions in one second, greatly reducing the measurement time. The operation interface of the software is simple and easy to be understood, and the measurement program and parameter setting can be easily written. With automatic focusing, automatic positioning and automatic measurement function, anyone operation can obtain stable measurement results.

The system can automatically identify the position and direction of the product. Products can be placed randomly and can be measured simultaneously. With 300*200mm large field of vision, one-time overall imaging, even if increasing the measurement position, the system will not increase the measurement time, greatly reducing the measurement time and improve the measurement efficiency.

The software functions are simple and easy to understand, with process instructions, operators can easily complete the product measurement program according to each instruction.

By adjusting the movement of the cross roller rail in microns, excellent straightness is achieved and errors caused by the movement of the moving platform are eliminated.

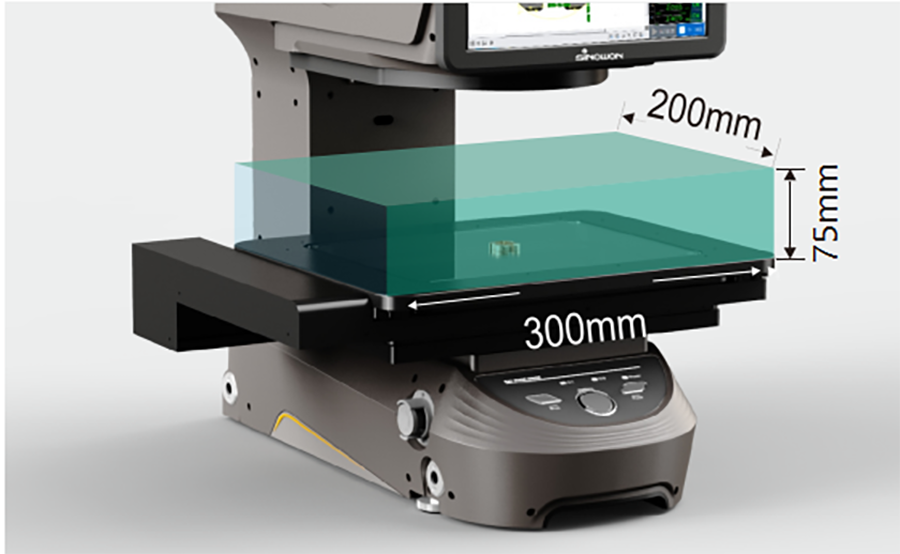

The maximum size of measuring objects allowed on the mobile platform is 300 mm × 200 mm and the height is 75 mm. The working stage adopts a new design that reduces the resistance of the motor and the feed screw to the limit. The moving distance is smaller and more stable, and the high precision measurement can be achieved without fixed measuring objects.

The maximum size of measuring objects allowed on the mobile platform is 300 mm × 200 mm and the height is 75 mm. The working stage adopts a new design that reduces the resistance of the motor and the feed screw to the limit. The moving distance is smaller and more stable, and the high precision measurement can be achieved without fixed measuring objects. The automatic focusing and edge invalid point automatic filtering function of the software can eliminate the error caused by different focusing and the edge invalid part of the product, so as to achieve stable detection results for anyone operation.

The automatic focusing and edge invalid point automatic filtering function of the software can eliminate the error caused by different focusing and the edge invalid part of the product, so as to achieve stable detection results for anyone operation. The automatic focusing and edge invalid point automatic filtering function of the software can eliminate the error caused by different focusing and the edge invalid part of the product, so as to achieve stable detection results for anyone operation.

The automatic focusing and edge invalid point automatic filtering function of the software can eliminate the error caused by different focusing and the edge invalid part of the product, so as to achieve stable detection results for anyone operation.

Accurately extract edges according to optimal lighting conditions

Light source sets different lighting, according to the different detection products, automatic debugging of lighting brightness, switching the best color lighting conditions.

Green Ring Light

White Ring Light

White Ring Light

With the combination of multiple variable adjustment lighting units, through the built-in brightness sensor for different environmental lighting, the system will adjust the height, brightness and angle of the light source to achieve the best visual effect, precise object edge.

IVS-302D

◆ Range(mm): 300X200X75 ◆ Ring Light (Adjustable) ◆ Auto Focus ◆ Double Magnification Telecentric LensIVS-100D

◆ Range(mm): φ100mm ◆ Ring Light (Adjustable) ◆ Auto Focus ◆ Double Magnification Telecentric LensIVS-202D

◆ Range(mm): 200X200X75 ◆ Ring Light (Adjustable) ◆ Auto Focus ◆ Double Magnification Telecentric Lens| Model | IVS-100D | IVS-202D | IVS-302D | ||

| Measuring Range | X | φ100 | 200mm | 300mm | |

| Y | 200mm | 200mm | |||

| Z | 75mm | 75mm | 75mm | ||

| FOV | High-Precision Mode | 26mm X 18mm | |||

| Wide-Field Mode | φ100mm | ||||

| Repeatability | High-Precision Mode | ± 1.5μm | |||

| Wide-Field Mode | ± 3μm | ||||

| Minimum Unit | 0.1μm | ||||

| Accuracy | High-Precision | Without Binding | ±1.5μm | ||

| With Binding | \ | ±2+L/150μm | ±2+L/150μm | ||

| Wide-Field | Without Binding | ±3μm | |||

| With Binding | \ | ±3+L/150μm | ±3+L/150μm | ||

| Weight | 33 Kg | 45 Kg | 50 Kg | ||

| Optical System | Camera | 1" 20MP BW Camera * 2 | |||

| Lens | Double Magnification Telecentric Lens | ||||

| Surface Light | Two-Ring Liftable Light | ||||

| Bottom Light | Green Parallel Bottom Light | ||||

| Capacity | 5 Kg | ||||

| Measuring Software | GD&T Software | ||||

| Power Supply | 220V±10%,50Hz | ||||

| Working Environment | Temperature: 20±3℃, Humidity: 30-80%, Vibration: <0.002g,15HZ | ||||

| Dimension (L*W*H) mm | 600*300*650mm | 600*410*650mm | 600*510*650mm | ||